Exploring the Role of Meat Processing in Food Redistribution: Cricket 999.com login, 11xplay online, Betbhai9 id

cricket 999.com login, 11xplay online, betbhai9 id: Exploring the Role of Meat Processing in Food Redistribution

Meat processing plays a crucial role in the food industry, providing consumers with a wide range of high-quality meat products. However, meat processing facilities also have the potential to contribute to food redistribution efforts, helping to reduce food waste and address food insecurity.

In this article, we will explore the role of meat processing in food redistribution and how these facilities can work towards a more sustainable and equitable food system.

The Importance of Meat Processing Facilities

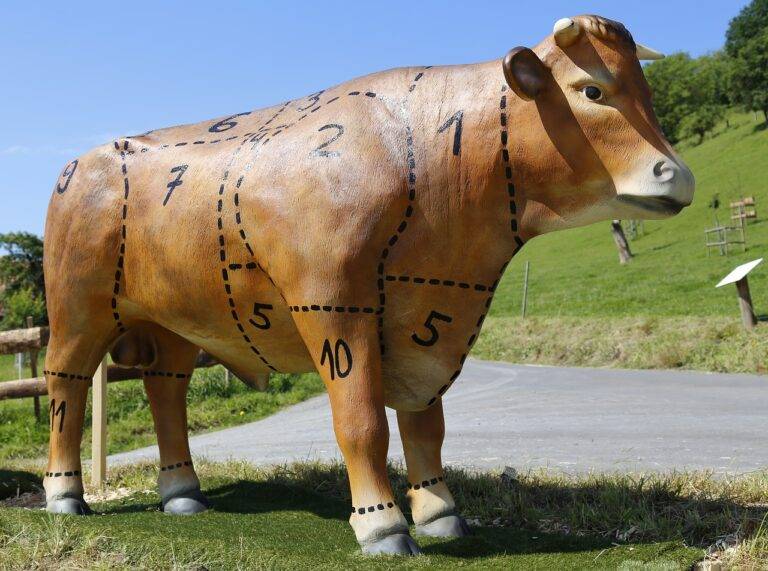

Meat processing facilities are responsible for converting raw meat into various consumer-ready products, such as sausages, burgers, and packaged cuts of meat. These facilities play a vital role in ensuring the safety and quality of meat products for consumers.

In addition to their primary role in providing meat products to consumers, meat processing facilities can also play a key role in food redistribution efforts. By partnering with food banks, non-profit organizations, and other stakeholders, these facilities can help divert surplus meat products from going to waste and instead redirect them to those in need.

How Meat Processing Facilities Can Contribute to Food Redistribution

There are several ways in which meat processing facilities can contribute to food redistribution efforts:

1. Donating Surplus Meat Products: Meat processing facilities often have excess inventory that may not meet specific market demands or quality standards. By donating these surplus meat products to food banks and other organizations, facilities can help ensure that these products do not go to waste and instead reach individuals facing food insecurity.

2. Developing Value-Added Products: Meat processing facilities can create value-added products from surplus meat products, such as pre-cooked meals, frozen patties, and canned goods. These products can be distributed to those in need or sold at a discounted rate to low-income consumers.

3. Collaborating with Food Redistribution Organizations: Meat processing facilities can partner with food redistribution organizations to streamline the donation and distribution process. By working together, facilities can ensure that surplus meat products are properly handled, stored, and distributed to those who need them most.

4. Implementing Waste Reduction Strategies: Meat processing facilities can also implement waste reduction strategies within their operations to minimize the amount of food that goes to waste. By optimizing production processes, improving inventory management, and reducing overproduction, facilities can help reduce food waste and increase the availability of surplus meat products for redistribution.

5. Educating Consumers: Meat processing facilities can educate consumers about the importance of food redistribution and how they can support these efforts. By raising awareness about food waste and food insecurity, facilities can inspire consumers to make more informed purchasing decisions and support organizations working towards a more sustainable food system.

Challenges and Opportunities

While meat processing facilities have the potential to make a significant impact on food redistribution efforts, there are also several challenges that they may encounter. These challenges include logistical constraints, regulatory requirements, and the need for strong partnerships with food redistribution organizations.

However, there are also opportunities for meat processing facilities to innovate and lead the way in sustainable food redistribution practices. By investing in technology, workforce training, and community engagement, facilities can develop more efficient and effective strategies for redistributing surplus meat products and reducing food waste.

FAQs

1. How can meat processing facilities ensure the safety and quality of donated meat products?

Meat processing facilities can follow strict safety and quality control protocols to ensure that donated meat products meet all regulatory requirements and food safety standards. This may include implementing proper storage and handling practices, conducting regular inspections and audits, and collaborating with food safety experts to ensure compliance.

2. What types of meat products are most commonly donated by meat processing facilities?

Meat processing facilities may donate a wide range of products, including fresh cuts of meat, frozen meat products, pre-cooked meals, and value-added products. The types of products donated may vary depending on market demand, production capacity, and partnership agreements with food redistribution organizations.

3. How can consumers support food redistribution efforts related to meat products?

Consumers can support food redistribution efforts related to meat products by purchasing products from companies that prioritize sustainability and social responsibility, donating to food banks and non-profit organizations, and advocating for policies that promote food waste reduction and food security.

4. What are some best practices for meat processing facilities looking to enhance their food redistribution efforts?

Some best practices for meat processing facilities looking to enhance their food redistribution efforts include conducting regular assessments of surplus inventory, establishing clear donation and distribution protocols, engaging with community stakeholders, and measuring the impact of their food redistribution initiatives.

In conclusion, meat processing facilities have the potential to play a significant role in food redistribution efforts, helping to reduce food waste and address food insecurity. By partnering with food banks, developing value-added products, collaborating with food redistribution organizations, implementing waste reduction strategies, and educating consumers, these facilities can make a positive impact on their communities and contribute to a more sustainable and equitable food system.